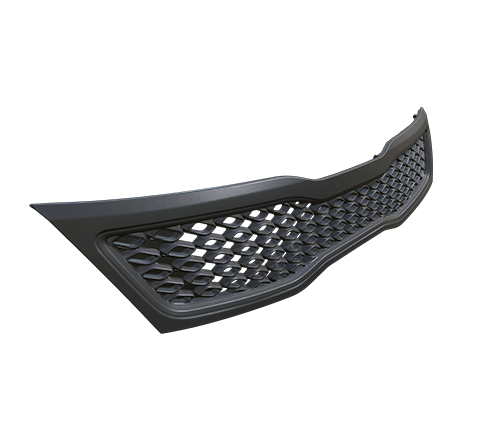

摩托车发动机盖

10分钟

7分钟

20分钟

扫描带孔物体时,要考虑一点,就是噪点太多有时会导致孔被堵——也就是说压根看不到这些孔,在成品3D模型中也不是您所要的效果,这就造成了一些麻烦,特别是在制造和逆向工程中。但是,如果在Artec Studio 15 AI驱动的HD模式下使用Leo扫描,就不会出现上述问题。噪点最低,孔不会被阻塞,能被顺利捕获,还可在最终成品中清晰可见。

看看这台摩托车发动机罩,无疑是项挑战,精密细节加黑色表面,提高分辨率意味着边缘更加锋利。这不仅能提升整个物体,同时也提升了小细节、细线,当然还有孔。

使用Leo扫描,最简单的解决方案成为了现实:实时查看您正在捕获的部分,所见即所得,它们会成为后期处理后的成品3D模型。

仔细浏览,观察其线条、细节、外形,这款3D模型以惊人的精度真实还原了原物。特别注意孔。使用配备AS15的Artec Leo,似乎曾经的不可能已成为了现实——不仅能扫描物体,还能精准捕获孔洞的负空间。